Sallie Whitlow has been in love with natural fibers for as long as she can remember. She is a knitter and long-time hand spinner who first became interested in alpacas (back in 1994) through working with their beautiful fleece. Her business, Sallie’s Fen Fibers, a mini-mill in Barrington, New Hampshire mostly processes alpaca, but also processes other fibers including wool, mohair, angora, and cashmere.

The mill has been operating for 10 years and is only getting better at producing an outstanding product.

Thanks to Britta McCarthy, a senior at the University of New Hampshire who reached out to us about her work with Sallie’s Fen Fibers, a mini mill in Barrington, New Hampshire, and a video she produced on Sallie’s fiber processing operation. We were more than happy to put it up here for our community to watch and also, to get to know more about Sallie and Britta.

Britta wrote to us: “I became deeply interested in sustainable fiber systems this past year and have focused my capstone research on natural fiber resources in New Hampshire. Sallie Whitlow puts an enormous amount of work into the functioning of the mill to the benefit of small, local fiber growers. It’s a great opportunity to help showcase the hard work that goes into fiber processing.”

We caught up with both Sallie and Britta to ask some questions about the mill and their passion for fiber.

Sallie Whitlow

You’ve had your mill for 10 years now. Did you start it first for you and then saw there was other business to be had?

The mill was started as a service to customers of Sallie’s Fen Alpacas, offering a post alpaca purchase service. The intent was always to process fiber from other farms. All of my new business was and still is mainly by word of mouth.

Do you have more people coming to you for processing over the past few years? Steady?

Business has been steady with maybe a downward trend over the last two to three years. This may reflect the fact that the number of alpaca farms is declining and many of the new ones are very small, maybe 3 or 4 alpacas, and the owners are not interested in doing anything with the fiber.

Is your business based mostly on alpaca?

I would estimate that 80% of the fiber processed is alpaca. The percentage of wool processed has been increasing as more of the sheep farmers are thinking of selling roving or yarn from their fiber as a way to increase the income from their flock.

What’s your favorite part of running Sallie’s Fen Fibers?

My favorite part is ending up with a product that the customer is happy with. I also have some ‘special projects’ for customers that are fun as they are outside the normal products generated by the mill.

Britta McCarthy

It’s so great to see the next generation of fiber enthusiasts. How did you get interested in sustainable fiber systems this past year?

Sallie Whitlow puts an enormous amount of work into the functioning of the mill to the benefit of small, local fiber growers. It’s a great opportunity to help showcase the hard work that goes into fiber processing.

How has your research on natural fiber resources in New Hampshire changed your ideas since you first started (expectations, challenges, heroes etc)?

My interest in natural fibers began with a search for canvas. I had previously worked for a great local business in Connecticut that produced handmade leather goods. I was hoping to take what I had learned from that experience and start selling items of my own. I naively thought that I would be able to find sustainably produced canvas made in the United States to make my own bags. I was shocked to find almost no options and soon fell down the fiber rabbit hole.

I was able to continue this deep dive into fiber and textile resources as part of my EcoGastronomy capstone. Much of what I have learned about food and agriculture as an Ecogastronomy major directly ties into sustainable fiber production. I will be continuing my project into my final coming semester, but it has been an eye opening experience so far. The video with Sallie is one half of my project, the other will be a research paper.

I’ve been shocked by the obvious lack of infrastructure we have left for fiber and textile production. Especially living in Dover, New Hampshire where the mill buildings are a constant reminder of our rich production history. That is not to say that the old methods of production were ideal, but they were nonetheless tied so closely with the community.

I have been greatly influenced by Rebecca Burgess and Fibershed. When I initially got into the subject I was able to learn a ton through the materials and research available on the website. I found Sallie’s mill through a directory on the site. I just finished reading Raw Material: Wool Working in the West by Stephany Wilkes and found it very inspiring. She is a really great writer and paints a vivid picture of the people she met shearing and in the fiber community.

What was it about Sallie’s business that was so interesting to you?

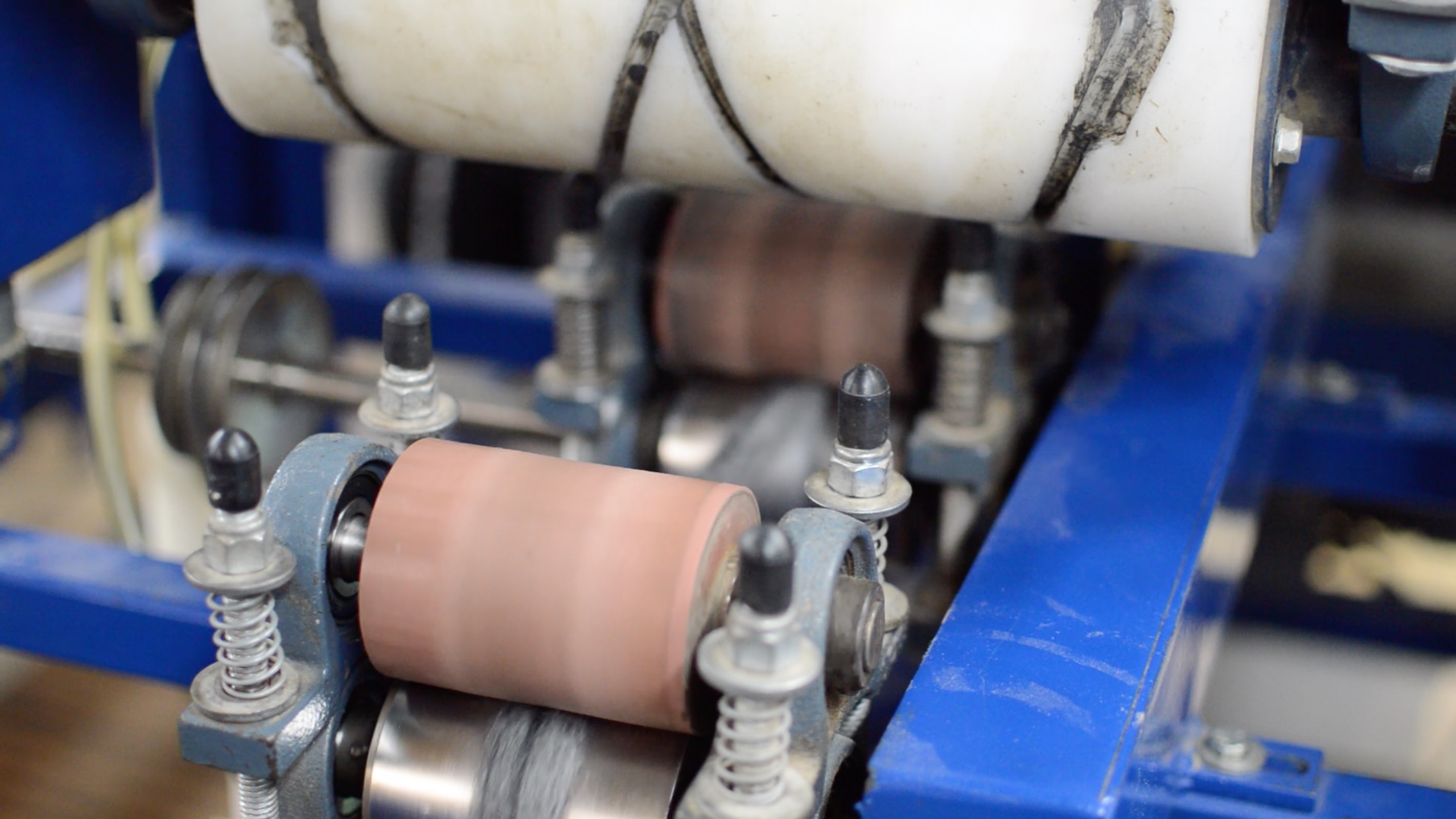

I found so few people doing what Sallie does, which was part of the initial draw. I also love working with my hands and admire people who do the same. It seemed like a perfect opportunity to learn about fiber production. Because we are largely detached from how our fiber, textile and clothing are produced I thought it might be of interest to people to see the process. It makes you appreciate the final product so much more when you see everything that goes into it.

Sallie and Amanda were super inspiring to work with. They have such a wealth of knowledge about the machinery and fiber they work with. They understand what it is to care for the animals from which the fiber comes (there are many alpacas on the property) and they understand the effort it takes to create a great product. In a system where the supply chain for most fibers and textiles is enormous and sometimes untraceable, being able to see production from start to finish was rewarding and satisfying. I didn’t work with the machinery myself, but Sallie was nice enough to let me come and observe them while they did the actual labor. Sallie explained the process and I filmed them over a few visits.

Looking forward and considering farm to fashion apparel, what do you think will be the biggest challenges? Greatest rewards?

Going forward I think we are going to see the fiber system transform in a similar way the food system has changed. I think there is a growing awareness about the cost of fast fashion and over production and consumption. There are a lot of brands tapping into increasing consumer desire for sustainable options. I think people will also start to seek out local options. The difficulty is that you can’t produce a local garment as easily as you can a fruit or vegetable because of the necessary infrastructure. You might have some wool, but you may not have access to someone like Sallie to process it. Or you may not have wool in a high enough quantity for facilities to accept it. That is, of course, where organizations like Fibershed come in and help bridge these gaps that make local production so difficult. In reading Stephany Wilkes book and working with Sallie, it is clear how much local fiber production not only benefits the land, but the people and community.

What do you hope to do from here with what you have learned?

I will be spending my final semester at the University of New Hampshire in Ascoli Piceno, Italy studying food systems. In the spring, I will graduate with my dual degree in Political Science and EcoGastronomy. So much I have also learned as a political science student also ties into the subject. I am hoping to work in an area related to sustainable supply chains for fiber and food or on policy matters related to food and fiber. I still would love to start a business making canvas bags, but have yet to hunt down a canvas producer that meets the criteria I am looking for.

Watch Britta’s video on Sallie’s Fen Fibers:

(All Images courtesy of Britta McCarthy)

Inspiring!

Tom Mcarty

Amazing!!! I am in awe at Brita’s determination!